Product Series

recommend products

Mechanical structure 1. Press steel body, according to the computer precision structure calculation. And force shape analysis, mining high-strength steel plate welding is completed, after the complete internal stress relief, integrated forming processing, to ensure the mechanical durability of the repeat accuracy. 2. After the hot plate is ground by multiple precision processing procedures, the parallelism and flatness of the single hot plate are all within ± 0.015 mm/m; The temperature tolerance is within ± 15°C. 3. White milling for piston. After grinding, the hardness is HRC500-550, no oil leakage resistance, oil seal using the world's general specifications. Convenient maintenance and repair. Electrical control unit 1. Advanced industrial-grade computer control system, based on Siemens WINCC chart control software and WINDOWS operating system. Compile software operation control program, temperature control and record temperature, pressure, vacuum degree, the third curve and data on the screen at the same time. 2. Humanized operation mode, simple and easy to learn, more than 5000 sets of production process formula and memory heating and cooling unit 1. The pump and other parts of the heating unit are all made of the highest grade accessories in the world, and the interior of the cooler is designed with stainless steel U-tube. There is no corrosion perforation and due to cold shrinkage and thermal expansion, resulting in cracking of the public security risk, one-piece production, the United States now does not occupy space. 2. Accumulation of years of practical operation experience and accurate complementary calculations. Ensure the safest and appropriate heating and cooling effects. The hydraulic system selects the hydraulic system components and pumps of Taiwan, the United States, Europe and Japan, and collects the design of the body circuit system to ensure the high stability and system accuracy of the hydraulic system operation. The vacuum device of the vacuum system adopts a systematic design that can be used for single pumping, two pumping, one pumping or three pumping, thus reducing the vacuuming time and improving the product quality. The gas-liquid separation barrel can effectively filter out the water content of the air pumped from the vacuum chamber, increasing the service life of the vacuum pump and reducing the number of maintenance.

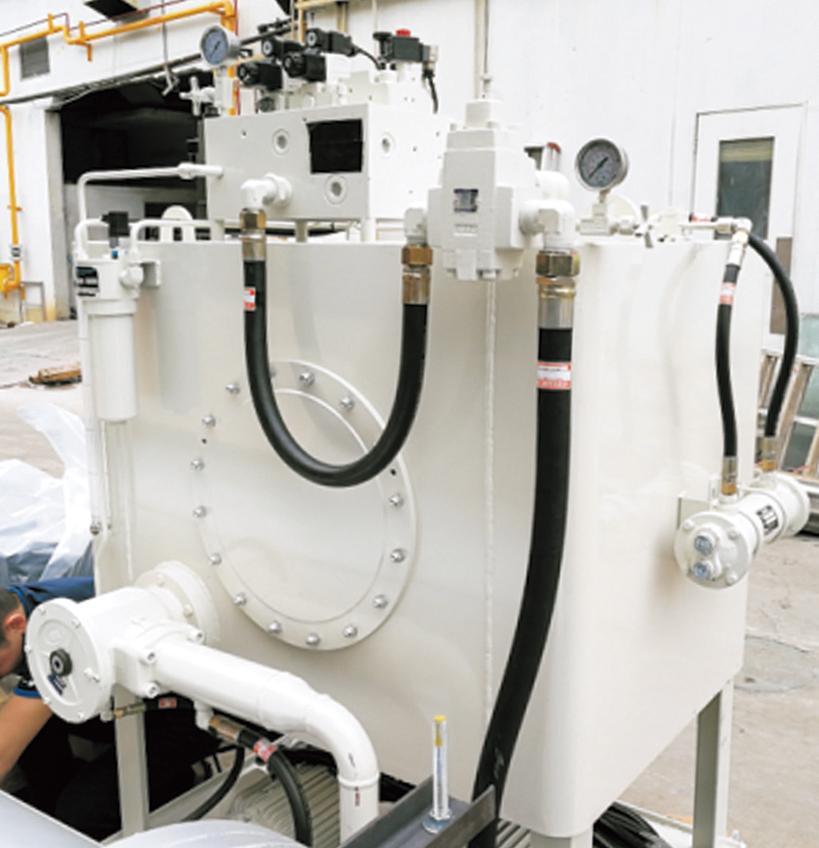

Oil pressure system OILPRESSURESYSTEM1. Taiwan mature integrated oil design, Taiwan production introduction. 2. Japan proportional pressure control valve, pressure control smooth, accurate, improve product pressure quality. 3. During the pressing process, the electricity can be interrupted to maintain the pressure, or it can be lowered manually.

Vacuum system VACUUMSY STEM 1. Vacuum system design can be a single pumping one, two or three pumping one, reduce the vacuum time, improve product quality, increase the service life of the vacuum pump, and reduce the number of maintenance. 2. The computer is equipped with vacuum system management, which can monitor the running time of the vacuum pump and remind the maintenance. During the maintenance, the monitoring system is selected to switch, and the press can be maintained without stopping, thus improving the production efficiency.