Product Series

recommend products

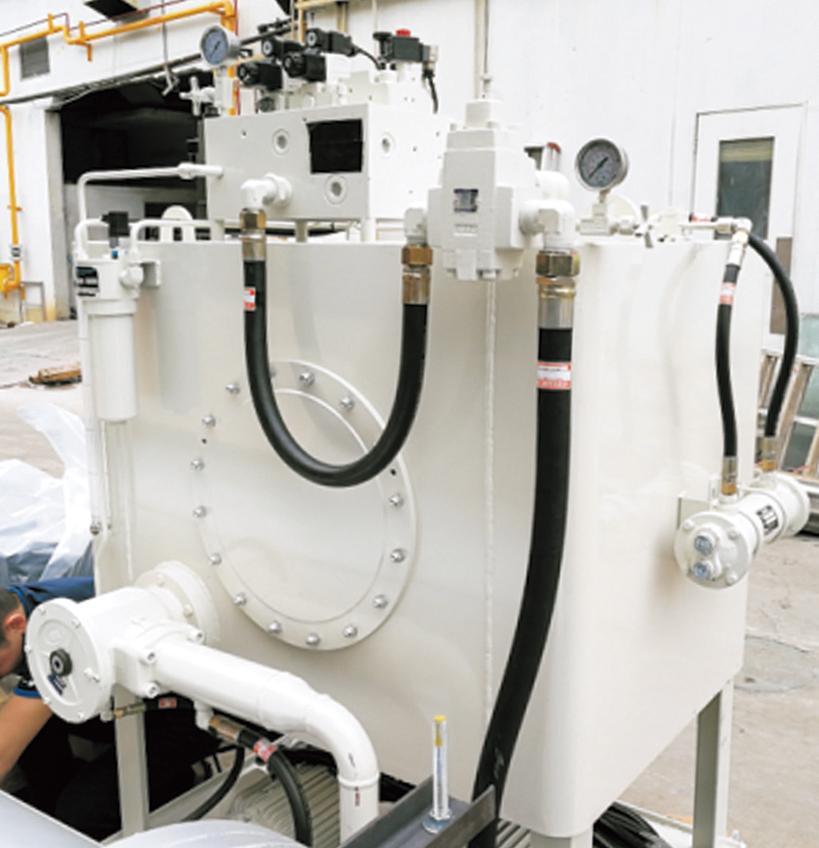

Fully automatic rubber compression molding machine

Model ModelHAXJ4-1150A Power Supply Specification Power specification380V/50HZ Total Pressure Pressure(Tons)150 Motor Specification (kw)Motor specification15 5.5 Layers Layer number2 Operation Mode Operating Mode Full Automatic automatic Workstation Number of work stations6-10 Type Type Plate/Column Plate type/ with 4 columns Working Plate Size (mm) Size of plate450 * 500 Heating Method Heating method Oil, Steam, Electric Oil/Steam/electricity Layer Spacing (mm) Total Power Consumption of Daylight between plate180 Total electricity (kw) Maximum Stroke of Master Cylinder (mm) Maximum stroke360 Machine Size (Length * Width * Height) Dimension (L * W * H) m8 * 2.3*1.75 Cylinder Stroke (mm) Pushing stroke600 Weight(Tons)17 Working Pressure (kg/cm2) Working pressure180

Technical Specifications are Indecative Machines may Undergo Variations and/or Modifications Without any Previous notice.

- Product Description

-

Technical parameters

Model HAXJ4-1150 Power specification 380V/50HZ Pressure(Tons) 150 Motor specification(kw) 15 2.2 Number of work stations 6 Operating Mode Full automatic Layer number 1 Type with 4 columns Size of plate 450*500/ Heating method Oil/steam/electricity Daylight between plate(mm) 350 Total electricity (kw) Maximum stroke(mm) 350 Dimension (L * W * H) m 7.25*1.4*2 Pushing stroke(mm) 400 Weight(Tons) 15 Working pressure (kg/cm2) 180 Feature1. One person can operate multiple stations at the same time, saving labor costs.2. automatic sliding in and out of the mold, easy operation, female operators can also be used.3. Just fix the lower mold on the skateboard to produce, and the mold change speed is fast.4. each station independent operation control, according to the production and maintenance needs, decided to start the number of stations, while saving electricity.5. according to the production demand flexibility to connect the number of stations, up to 6 stations can share a system.SUITABLE FORMonochrome and multicolor rubber soles, conductive rubber, automotive parts and various rubber finished molding, or other thermosetting products.Remarks: The above technical specifications are for reference only and are subject to change or modification without prior notice.

Tag:

Product inquiry

Related Products