Product Series

recommend products

EVA small foaming machine

Technical Parameters/TECHNICAL PARAMETERS Model Model Total Pressure Pressure(Tons) Working Plate Size of Plate (mm) Cylinder Diameter Dia.of cylinder (mm) Stroke (mm) Electric Heating Power Heating (kw) Motor Power (kw) Total Power Consumption Total Electricity (kw) Machine Size Dimension (L * W * H) m Weight (KG) HACJ-200T200600 * 6003604509.95.5162*1.4*2.23600 HACJ-250T250650 * 70042050011.77.5202.1*1.5*2.54600 HACJ-300T300650 * 75045050011.77.5202.1*1.5*2.54800 HACJ-400T400650 * 70050050011.711232.4*1.6*2.76000 HACJ-400T400750 * 80050050014.411262.4*1.6*2.76200 Features FEATURE1 and hydraulic control adopt imported well-known brands, hydraulic accessories, components, optional computer automatic control system. The movement is fast, stable, low noise and smooth. 2, another cooler, filter, protection to extend the life of hydraulic parts, so that the company has the best production performance. The scope of application SUITABLEFOR imitation porcelain tableware, ashtrays, daily necessities, handicrafts, toys and other thermosetting products. Note 1: Another 400T-500T pressure is available. Note 2: The above technical specifications are for reference only and are subject to change or modification without prior notice.

Technical Specifications are Indecative Machines may Undergo Variations and/or Modifications Without any Previous notice.

- Product Description

-

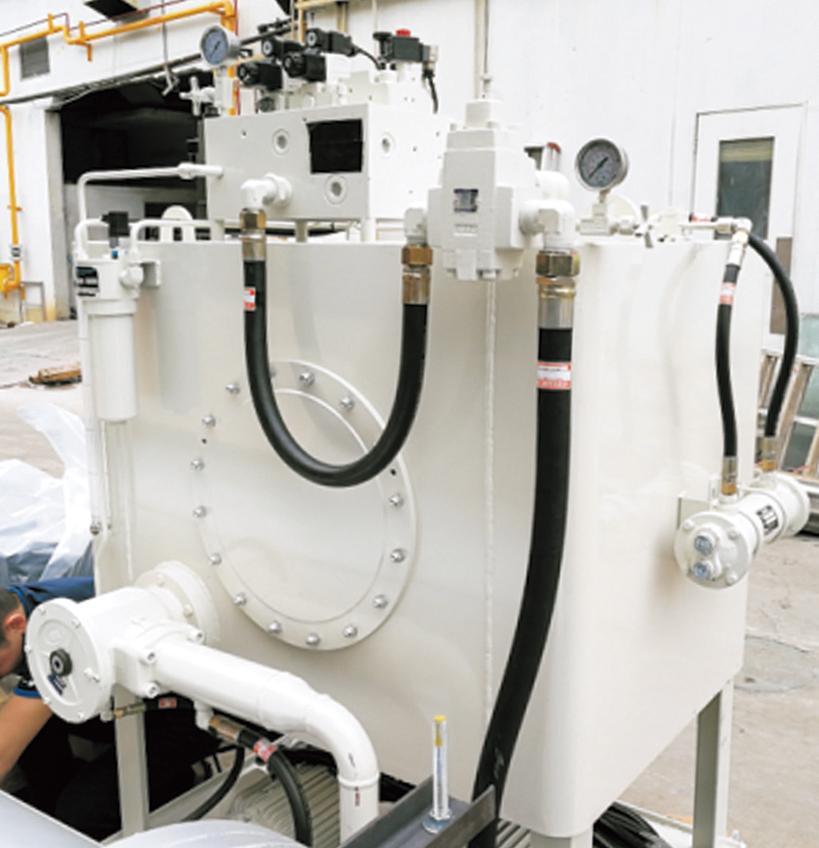

Technical parameters

Model Model HAXF-2150 HAXF-2200 Total pressure Pressure(Tons) 150 200 Number of workstations Work stations 6-10 6-10 Number of layers Layer number 2/3 2/3 Size of working plate (mm) Size of plate 550*550 600*600 Layer spacing (mm) Daylight between plate 260 260 Maximum stroke of master cylinder (mm)

Maximum stroke 520 520 Working pressure (kg/cm2) Working pressure 200 200 Power Supply Specifications Power specification 380V/50HZ 380V/50HZ Motor power (kw) Motor specification(kw) 15 0.75 15 0.75 Machine size (length * width * height)

Dimension (L*W*H) m 11.5*1.8*3 12.2*1.8*3 Weight Weight 18 20 Heating mode Heating method Oil/steam/ electricity Total electricity consumption Total electricity (kw) Feature1, PC and PLC control system automatic control program, simple operation.

2. Rise fast, keep the pressure for a long time, and the pressure will automatically rise in the process of adding sulfur to ensure the quality.

3. Special rapid release valve, mold opening and lowering, fast speed, and can be adjusted freely.

4. The pressure relief speed and delayed mold opening after pressure relief can be adjusted according to the characteristics and thickness of the finished product, which is suitable for the development of new products and improves quality.

5. Special design hot plate, uniform heat.

6, regardless of fully automatic or semi-automatic models, have the above characteristics.

SUITABLE FOREVA or PVC foam board, beach shoes, rubber foam or other materials for foaming.

The above technical specifications are for reference only and are subject to change or modification without prior notice.

Tag:

Product inquiry

Related Products