What is the copper clad laminate press produced by the manufacturer of copper clad laminate press?

Release time:

2021-07-06

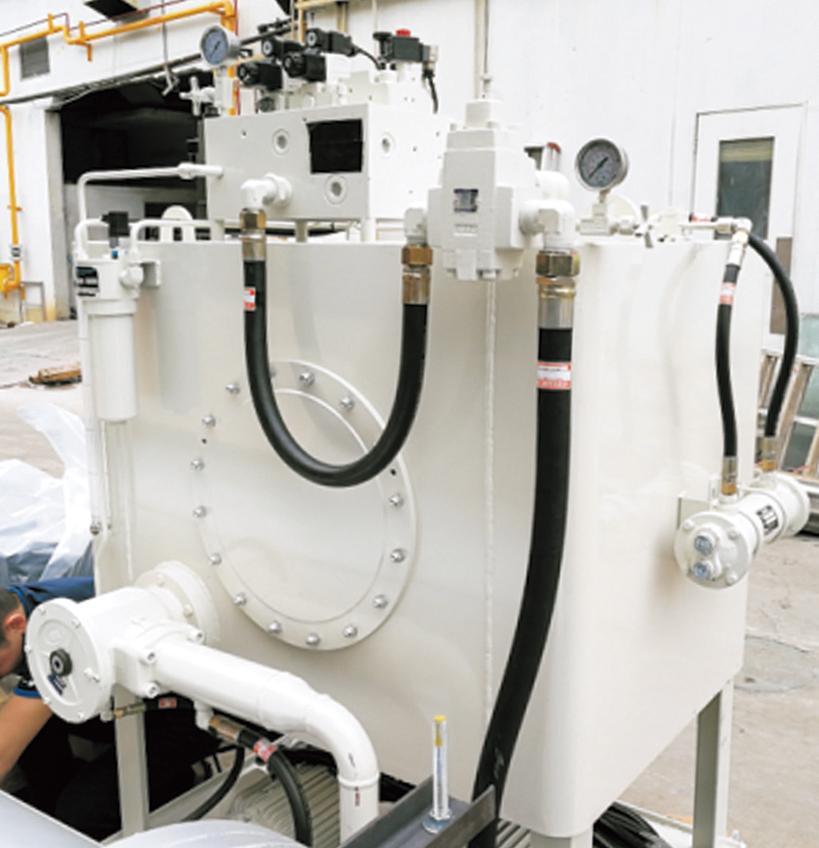

The copper clad laminate press produced by the manufacturer of copper clad laminate press is a plate-shaped material made of electronic glass fiber cloth or other reinforced materials soaked with resin, covered with copper foil on one or both sides, and made by hot pressing, referred to as copper plate. Printed circuit boards with various forms and functions are selectively processed, etched, drilled, copper plated and other processes on the copper foil to produce different printed circuits.

Copper Clad Laminate Press ManufacturerProducedCopper clad laminate press is a plate-shaped material made by soaking electronic glass fiber cloth or other reinforced materials with resin, covering copper foil on one or both sides, and hot pressing. Printed circuit boards with various forms and functions are selectively processed, etched, drilled, copper plated and other processes on the copper foil to produce different printed circuits. Printed circuit boards mainly play the role of interconnection conduction, insulation and support, and have a great influence on the signal transmission rate, energy loss, and characteristic impedance of the circuit. Therefore, the performance, quality, processability in the manufacturing process, manufacturing level, manufacturing cost, long-term reliability and stability of printed circuit boards depend to a large extentccl.

Copper Clad Laminate Press ManufacturerProducedCopper clad laminate press is a plate-shaped material made by impregnating electronic glass fiber cloth or other reinforced materials with resin, covering one or both sides with copper foil, and hot pressing, called copper foil laminate(Copper Clad Laminate,CCL), referred to as copper foil plate.

As a substrate material for the manufacture of printed circuit boards, printed circuit boards mainly play the role of interconnection conduction, insulation and support, and have a great influence on the signal transmission rate, energy loss, and characteristic impedance of the circuit. Therefore, the performance, quality, processability in manufacturing, manufacturing level, manufacturing cost, long-term stability and stability of printed circuit boards depend to a large extentccl.

CclWith the development of electronic information and communication industry, the manufacturing industry is a sunrise industry with broad prospects for development, and its manufacturing technology is a multi-disciplinary, mutual penetration and mutual promotion technology. The electronic information industry, especially the printed circuit industry, is developing at the same time and is inseparable. Its progress and development has been driven by the innovation and development of electromechanical products, semiconductor manufacturing technology, electronic mounting technology and printed circuit board manufacturing technology.

At present, copper clad press manufacturersProducedCopper Clad Laminate PressofEpoxy resin copper plate production of flame retardant products accounted90%Above. From a security perspective, users need products throughULSafety certification, flame retardant to achieveV-0Level. In order to meet the above requirements, a large number of brominated epoxy resin is used in the production of flame retardant sheet. Some foreign research institutions have proposed that halogen flame retardants will produce toxic substances during combustion, which will endanger human health and pollute the environment. There is strong international concern, particularly in Europe, about this issue. European Community(EC)The Environmental Protection Commission has proposed a deadline to ban the use of halogen-containing flame retardants in electrical and electronic products. The development of halogen-free flame retardant copper clad laminate has become an important issue in the industry and is imperative. From a chemical point of view, in addition to halogen elements(F,Cl,Br,I)Outside, andVof the clanN,Pand other elements. Experiments show thatNandPThe introduction of such elements into the epoxy resin system, coupled with appropriate flame retardants, can achieve a satisfactory flame retardant effect. It is well known that phenolic resin can be used as a curing agent for epoxy resins. Using phenolic resin to modify epoxy resins can increase the cross density of epoxy resins, improve heat resistance, and reduce the coefficient of thermal expansion. The introduction of nitrogen-containing components into the molecular structure of the phenolic resin and the use of the nitrogen-containing phenolic resin as an epoxy resin modifier can not only improve the flame retardancy of the epoxy resin, but also improve the heat resistance and dimensional stability.

Tag:

Previous Page

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas