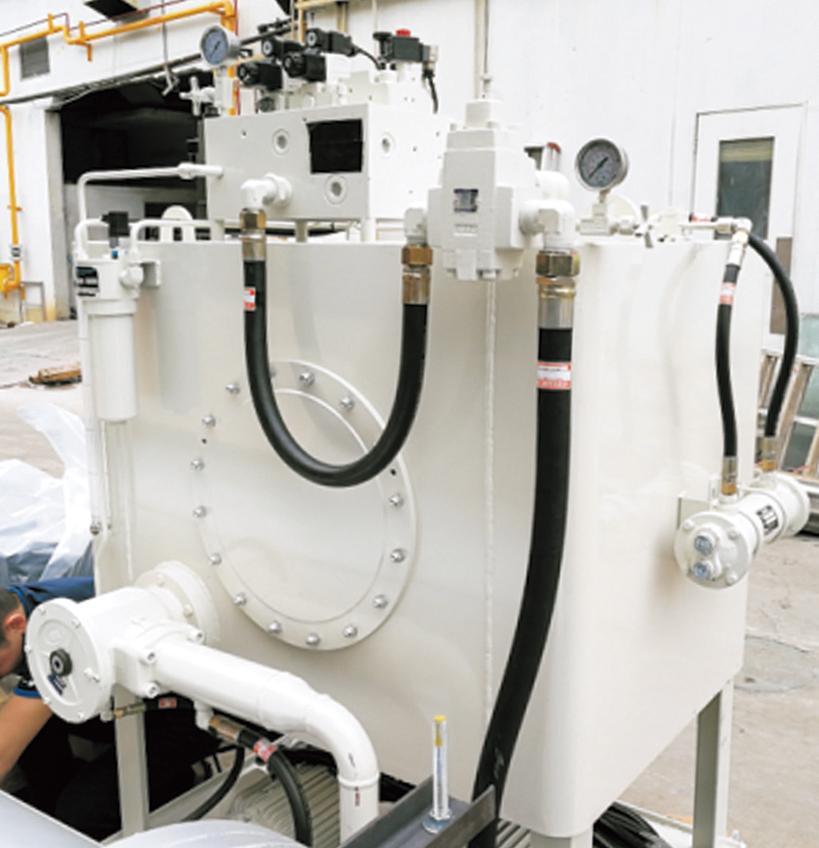

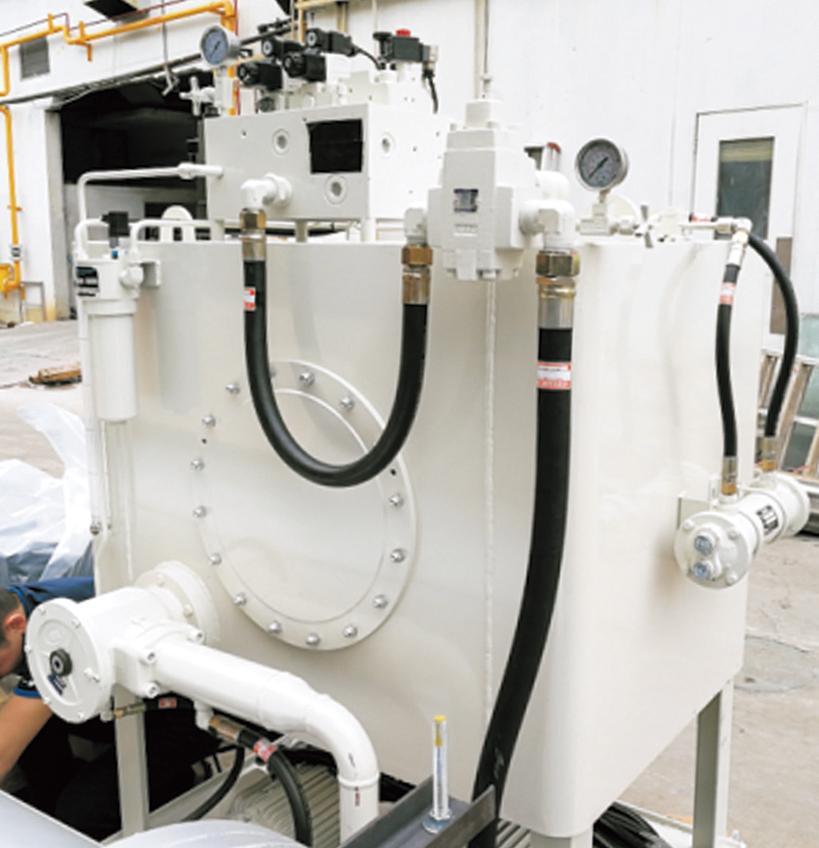

PCB laminator for printed circuit board laminate processing

Release time:

2021-07-17

A PCB laminate is a circuit board that is used to connect circuits. When the printed circuit board laminate is processed, it is necessary to laminate the printed circuit board laminate. But the current PCB laminator design is unreasonable, there are still some shortcomings. When laminating the printed circuit board laminate, the printed circuit board laminate cannot be firmly fixed, which makes it easy to move during the lamination process. In addition, when the PCB laminate is laminated, the dust on the surface cannot be removed, which will affect the lamination effect of the PCB laminate.

PCBLaminate is a circuit board used to connect circuits. When the printed circuit board laminate is processed, it is necessary to laminate the printed circuit board laminate. But at presentPCBThe design of the laminating machine is unreasonable, and there are still some shortcomings. When laminating the printed circuit board laminate, the printed circuit board laminate cannot be firmly fixed, which makes it easy to move during the lamination process. Also in laminatedPCBWhen laminating, the dust on the surface cannot be removed, which will affectPCBLamination effect of the laminate. Therefore, those skilled in the art provide a method for the processing of printed circuit board laminates.PCBlaminator to solve the problems raised in the above background.

Technical personnel provide a method for processing printed circuit board laminates.PCBLaminating machine to solve the problems raised in the above background technology. In order to achieve the above purpose,PCBThe laminating machine adopts the following technical scheme: a kind of for the processing of printed circuit board laminates.PCBThe laminator includes a workbench. Two stops are symmetrically arranged on the upper surface of the workbench. Two servo motors are symmetrically embedded on one side of one stop. One end of the servo motor is horizontally connected with the screw. One end of the screw is rotatably connected with one side of the other stop. A base is horizontally arranged between the two stops between the two screws. A sliding block is sleeved on the outer surface of the screw. The front upper surface of the sliding block is provided with a gap, cylinders are embedded in the upper surfaces of the two sliding blocks, the lower ends of the two cylinders are respectively fixedly connected with the upper surfaces of the two ends of the connecting shaft, the lower ends of the supporting springs are fixedly connected with the inner lower surface of the notch, one side of the two sliding blocks above the screw is provided with a connecting block, the front surface of the connecting block passes through the connecting pipe, the other end of the connecting pipe is fixedly connected with the front surface, the upper surface of the base is provided with two fixing seats on one side of one fixing seat. The outer surface of the connecting shaft is sleeved with a press cylinder, and the press cylinder is a rubber material component. An internal thread matching the screw is arranged inside the slider, and the outer surface of the screw is coated with antirust paint. The lower surface of the slider is vertically connected with a pulley, and the upper surface of the worktable is provided with a sliding groove corresponding to the pulley. The lower surface of the connecting pipe is uniformly connected with a cleaning nozzle, one end of the connecting pipe is fixedly connected with a hose, and one end of the hose is fixedly connected with one end of the gas compressor. A sliding rod is vertically arranged on the lower surface of the two ends of the two fixing seats, and a groove corresponding to the sliding rod is arranged on the upper surface of the base. The sliding rod is arranged in the groove, and the lower end of the sliding rod is rolled with a roller. The inner lower surface of the groove is in rolling contact; one side of the sliding rod is horizontally connected with a fixed spring, and one end of the fixed spring is fixedly connected to one side in the groove, the other side of the second fixing seat is fixedly connected at the middle position.

Compared with the existing technology, the above.PCBThe beneficial effects of the laminator are: the structure design of the device is scientific and reasonable, and the circuit board laminate can be laminated well, so that the quality of the produced circuit board laminate is better; when the printed circuit board laminate is laminated, the printed circuit board The laminate can be firmly fixed to prevent the printed circuit board laminate from moving and affecting the lamination effect of the printed circuit board laminate; when the printed circuit board laminate is laminated, the dust on the surface of the printed circuit board laminate can be blown by setting air compressor.

Tag:

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas