The structure of the pcb laminating machine!

Release time:

2021-09-16

Pcb laminating machine production methods are mainly manual pressure type and automatic pressure type two forms. The former is operated manually and pressurized by screw feed; the latter can be controlled electrically. However, the current two laminators have two common shortcomings, one is that the card time is too long, usually takes 10 to 20 minutes; second, the quality of the card can not be guaranteed by 100, can not meet the conference center on-site production certificate and personalized personnel to swipe the card and other needs.

pcb laminating machine production methods are mainly manual pressure type and automatic pressure type two forms. The former is operated manually and pressurized by screw feed; the latter can be controlled electrically. However, the current two laminators have two common shortcomings, one is that the card time is too long, usually takes 10 to 20 minutes; second, the quality of the card can not be guaranteed by 100, can not meet the conference center on-site production certificate and personalized personnel to swipe the card and other needs.

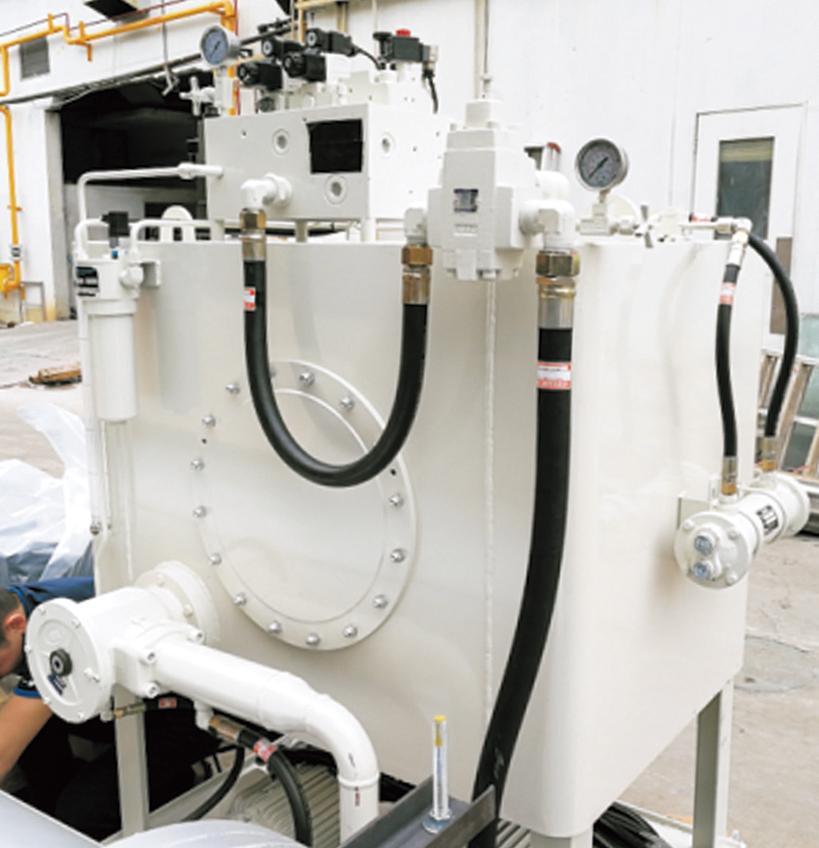

The pcb laminator includes a main frame, an air pump, a cooling water circulation system, a cooling water air cooling system, an electrical control system, structural parts of a cooling tower and a heat tower, automatic instrument control and automatic display parts; the air pump and cooling water The water circulation system is arranged in the lower part of the main frame, the cooling water air cooling system is arranged on one side of the main frame, and the electrical control system is arranged inside the frame.

The structure of cooling tower and thermal tower includes: the frame fixed with left and right sliding guide rails perpendicular to the upper and lower beams, the air-hydraulic cylinder that gives lifting and processing pressure to the cooling tower and thermal tower, the cooling tower composed of the upper block of the cooling tower and the lower block of the cooling tower, and the thermal tower composed of the upper block of the cooling tower and the lower block of the thermal tower, it is composed of the inlet of the laminated body located between the upper block and the lower block of the thermal tower. It is composed of a hydraulic cylinder and a cylinder. In order to speed up the cylinder head and cooling, the cooling force buffer and the return of the piston rod, the piston of the cylinder The top is connected with a disc spring, and the cylinder is connected with the above-mentioned air pump to control the pressure of the hydraulic cylinder.

Hongan (Fujian) Machinery Co., Ltd. is a professional manufacturer integrating design, electromechanical and manufacturing. Since its establishment, it has been adhering to the corporate philosophy of "people-oriented, creating the future together. The company produces PCB laminating machine, copper clad laminate press, PCB vacuum laminating machine, PCB laminating machine, high temperature vacuum laminating machine, PCB vacuum laminating machine, high temperature laminating machine, reasonable design, material selection, durable.

Tag:

Previous Page

Next Page

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas