PCB vacuum laminator supplier: The working principle of PCB vacuum laminator!

Release time:

2021-10-18

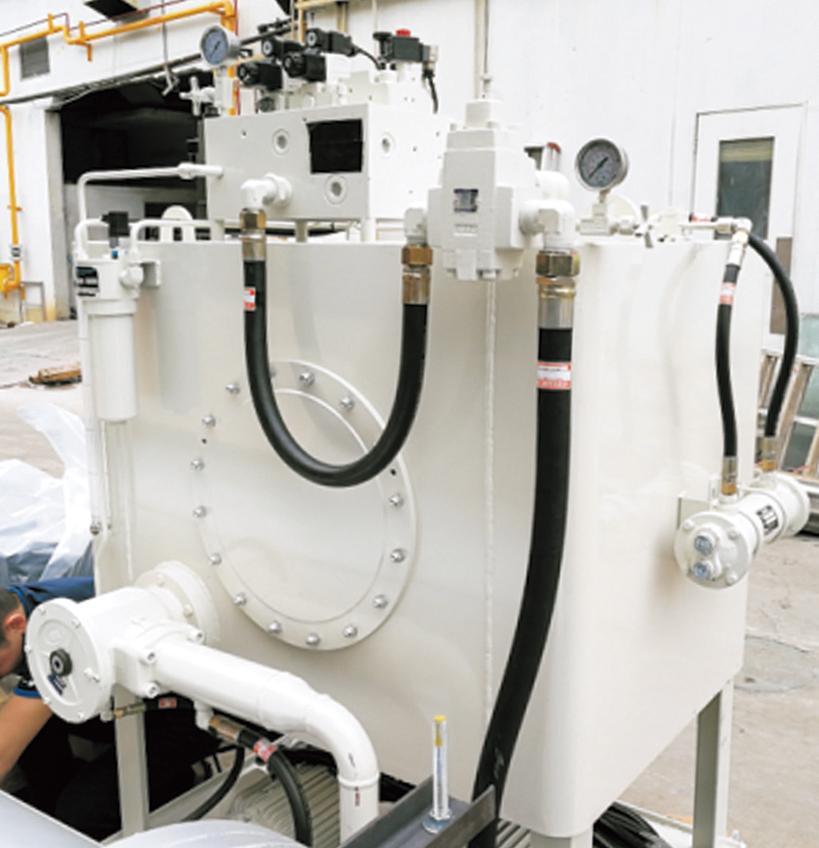

When the machine is powered on, the upper and lower heating plates of the machine begin to heat up, and the vacuum system starts to work, so that the space in the working area is close to the vacuum state, and the air between the pressing material and the material is completely discharged.

When the machine is powered on, the upper and lower heating plates of the machine begin to heat up, and the vacuum system starts to work, so that the space in the working area is close to the vacuum state, and the air between the pressing material and the material is completely discharged.

When the temperature reaches the melting temperature of the prepreg, the prepreg melts to adhere closely to the copper foil. The subsequent process is the process of heat preservation and cooling, which makes the prepreg and copper foil become one, fully meet the requirements of the product and eliminate the stress in the middle of the material. If you want to make a multilayer board, you can do the inner layer board according to the above requirements, plus semi-cured sheet, copper foil can be completed, in which the role of semi-cured sheet is to play the role of insulation and reinforcement.

For example, the motherboard of a computer is an example. The principle, process and method of other 6-layer 8-layer boards are the same. For example, the motherboard of a computer is an example. The principle, process and method of other 6-layer 8-layer boards are the same.

Enter the correct program, board length, board width, and number of boards according to engineering specifications. Check whether the temperature, oil pressure, cold pressure and time are set correctly. After confirming the temperature of the hot plate, send the steel plate to be pressed into the press. Check the pressure setting value, pressure actual value, temperature setting value, temperature actual value, vacuum setting value and actual value after hot pressing rise. After the hot pressing is complete, the hot plate is automatically lowered, the steel plate is taken out and sent to the cold press, and cold pressing is started. After the cold pressing is complete, the pressing operation is completed when the pressure plate automatically descends.

Tag:

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas