What is the working principle of the PCB vacuum laminator?

Release time:

2021-06-23

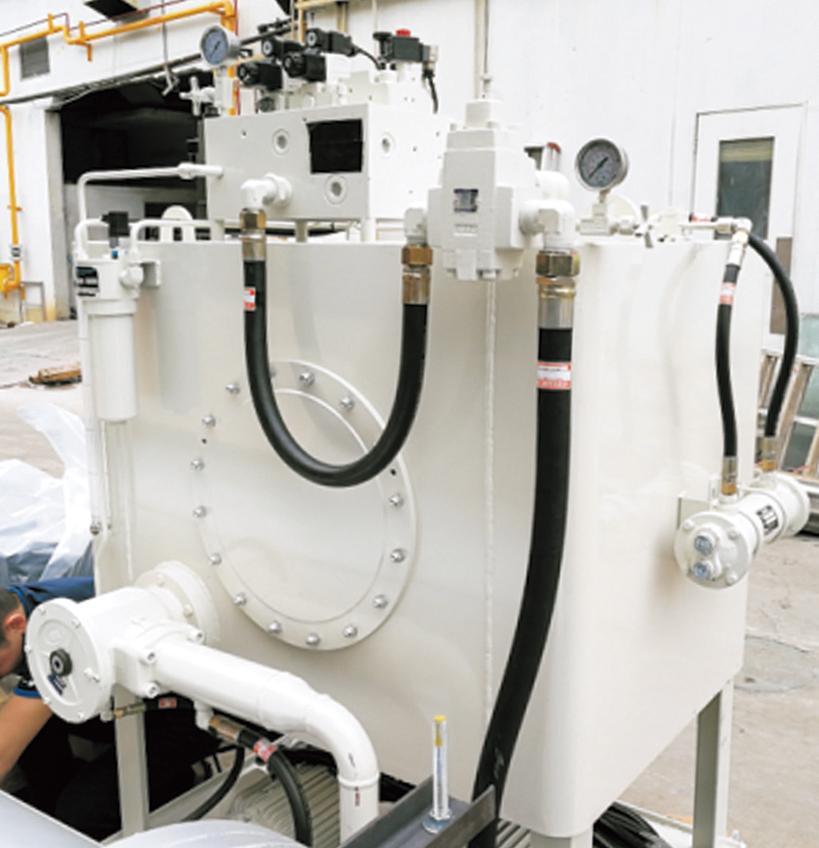

PCB vacuum laminator is a mechanical device that compresses multi-layer substances under vacuum conditions. No matter what the PCB vacuum laminator is suitable for, its working principle is the same. It is to apply a certain pressure to the surface of the multi-layer material and press these materials closely. Different work according to the layers of purpose, extrusion conditions vary.

What is the working principle of the PCB vacuum laminator?

PCB vacuum laminator is a mechanical device that compresses multi-layer substances under vacuum conditions. No matter what the PCB vacuum laminator is suitable for, its working principle is the same. It is to apply a certain pressure to the surface of the multi-layer material and press these materials closely. Different work according to the layers of purpose, extrusion conditions vary.

What is the working principle of the PCB vacuum laminator?

After the machine is powered on, the upper and lower heating plates of the machine start to heat, and the vacuum system works to make the space of the work area close to the vacuum state, so that all the air between the compressed material and the material is discharged. After the temperature reaches the melting temperature of the radiused plate, the radiused plate melts and is in close contact with the copper foil. The next process is the heat preservation and cooling process, which combines the prepreg and the copper foil together to fully meet the product requirements and eliminate the stress in the material. To make a multi-layer board, the inner layer board can be made as described above, and the semi-cured board and copper foil can be used. The role of the semi-cured board is insulation and reinforcement. The motherboard of a computer is an example. The principle, process and method of the other 6-layer 8-layer board are as above.

1. Enter the correct program, board length, board width, and number of boards according to the engineering specifications.

2. Verify that the temperature, hydraulic pressure, cold pressure and time settings are correct.

3. After confirming the temperature of the hot plate, the pressed steel plate is sent to the press.

4. After the hot pressing is increased, the pressure setting, actual pressure value, temperature setting value, actual temperature value, vacuum setting value and actual value should be checked.

What are the structural characteristics of the PCB vacuum laminator?

1. Press steel structure main body, computer precision structure calculation and force deformation analysis, high-strength steel plate welding is completed to eliminate all internal should be

Force, the overall molding process, to ensure the mechanical continuity of repeated accuracy.

2. After the hot plate is polished by multiple precision processing procedures, the parallelism and flatness of a single hot plate are within 0.015 mm/m. Temperature tolerance within 1.5.

3. The piston is milled in white. After polishing, the hardness is HRC50o ~ 55o. The oil seal uses the oil seal of the world's general specifications, which is easy to maintain and repair.

Electric control device

1. Based on the advanced industrial computer control system, IFlX chart control software and WlNXP operating system, compile the software operation control program, and simultaneously control and record the temperature, pressure, vacuum, third curve and data on the screen.

2. Humanized operation mode, easy to learn, 5000 multiple production processes and memory.

3. Select the hydraulic system main line table, the United States, Europe, Japan's hydraulic system components and pumps, collecting body circuit system design, to ensure the high stability of the hydraulic system operation and system accuracy.

Heating and cooling device

1. The heating device pump and other parts are selected from the world's best parts. The interior of the cooler is designed with stainless steel U-shaped tube, which will not rust, and the danger of cracks due to perforation and thermal expansion due to cold shrinkage. The overall production will not take up space.

2. Accumulate years of practical operation experience and accurate supplementary calculations to ensure safe and proper heating and cooling effects

Tag:

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas