How to control the temperature of PCB vacuum laminator?

Release time:

2021-06-26

The PCB vacuum laminator has achieved good processing results, and the work of the PCB vacuum laminator has become a very important part of the heating process. Only the vacuum laminator circuit board can reach the ideal state when using temperature control, and the effect is very good during processing. Therefore, more and more people need to better analyze the temperature control processing related functions of the PCB vacuum laminator in order to better understand the PCB vacuum laminator.

How to control the temperature of PCB vacuum laminator?

The PCB vacuum laminator has achieved good processing results, and the work of the PCB vacuum laminator has become a very important part of the heating process. Only the vacuum laminator circuit board can reach the ideal state when using temperature control, and the effect is very good during processing. Therefore, more and more people need to better analyze the temperature control processing related functions of the PCB vacuum laminator in order to better understand the PCB vacuum laminator.

How to control the temperature of PCB vacuum laminator?

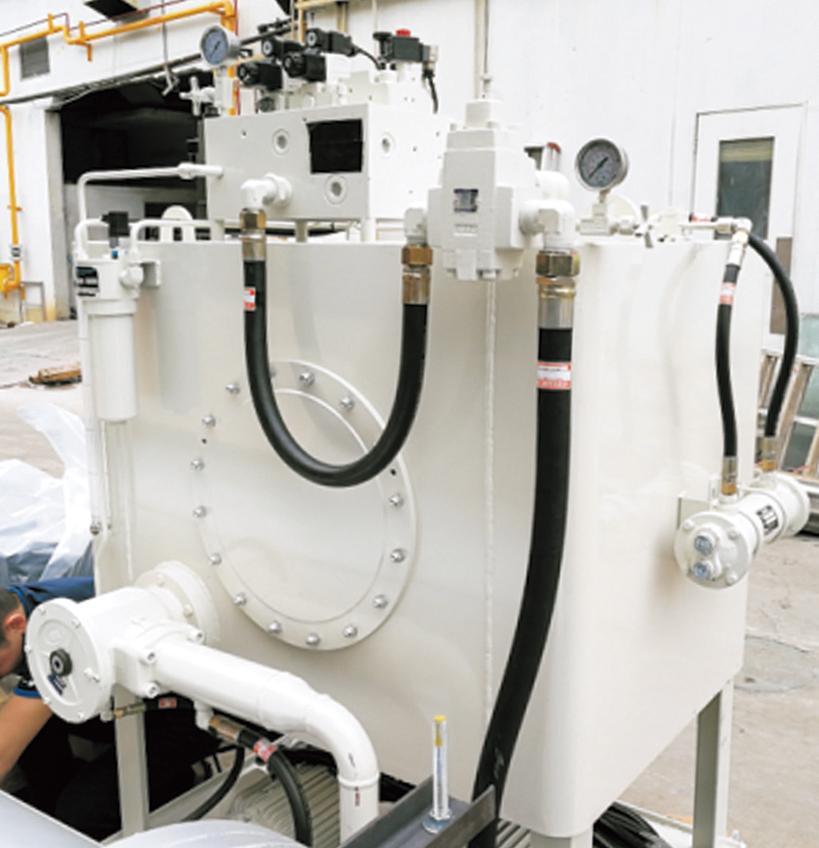

Temperature control of vacuum high temperature hot pressing: First of all, we must master the composition of heating technology. In other words, in the heating process of the PCB vacuum laminator, the heater and the hot plate will become two very important components. Only a careful analysis of the two parts of the heating situation, in order to understand the actual product heating effect. During the heating process, the product power is very large, the heat conduction is very fast, the flatness of the electric heating plate during the production process is very high, and the high temperature resistance effect is also very strong. Then, in the case of ideal temperature control, when performing a specific heating operation, the staff will find that the actual temperature control effect of the actual air compressor in the operation is very ideal. The composition of the temperature bar is very high in temperature sensitivity, not only in thermal speed, but also in practical accuracy. From a structural point of view, embedding this structure also makes things better. The temperature control process of PCB vacuum laminator has many aspects of understanding, so that people can well analyze the temperature control of the product. In the specific work process, workers do not have to worry about the unsatisfactory temperature control of the equipment, and the overall process and temperature effect have been well controlled.

PCB vacuum laminator cracks should be how to solve?

When a crack occurs in the PCB vacuum laminator, a non-woven semi-cured sheet is placed around the copper block to fill the gap, but it is not enough to rely on the semi-cured sheet to fill the gap. How should it be solved?

1. Combine the tooth groove and plate rivets made in advance.

2. Set the prepreg sleeve on the copper plate and put it into the blind groove.

3. Place the special-shaped film and the prepreg on the steel plate, place the copper plate on the prepreg, and cover the copper foil.

4. Put it into a vacuum extruder to pressurize.

Using a vacuum extruder to press the prepreg of non-woven epoxy resin to charge the solution, the adhesive content is very high, we use its special function to fill the gap around the copper block, the effect is very obvious. The depth of the gap around the copper block is deep, the gap is large, and the charging capacity of the prepreg reaches the limit, which cannot fully fill the gap. This scheme can be expanded in parallel. In addition, the editor also reminds everyone that the vacuum degree of the vacuum extruder must be guaranteed.

Tag:

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas