Pcb laminating machine production method

Release time:

2021-07-05

With the development of economy, the application of all kinds of card certificates is more and more extensive, and their varieties, specifications and types are increasing, and some characteristic personalized card certificates are emerging one after another. In order to adapt to the production and production of these various kinds and small batch of card printing certificates, various small card printing equipment have been born. pcb laminator is one of the small card printing equipment matched with this manual card printing machine. Let's learn about the production method of pcb laminator!

With the development of economy, the application of all kinds of card certificates is more and more extensive, and their varieties, specifications and types are increasing, and some characteristic personalized card certificates are emerging one after another. In order to adapt to the production and production of these various kinds and small batch of card printing certificates, various small card printing equipment have been born. pcb laminator is one of the small card printing equipment matched with this manual card printing machine. Let's learn about the production method of pcb laminator!

At present, the production methods of small pcb laminator sold on the market mainly include manual pressure type and automatic pressure type. The former is operated manually and pressurized by screw feed; the latter can be controlled electrically. However, the current two laminators have two common shortcomings, one is that the card time is too long, usually takes 10 to 20 minutes; second, the quality of the card can not be guaranteed by 100, can not meet the conference center on-site production certificate and personalized personnel to swipe the card and other needs.

In order to overcome the above shortcomings of the existing small laminator, the utility model provides a high-speed laminator to improve the discharge speed of the card and the quality of the card.

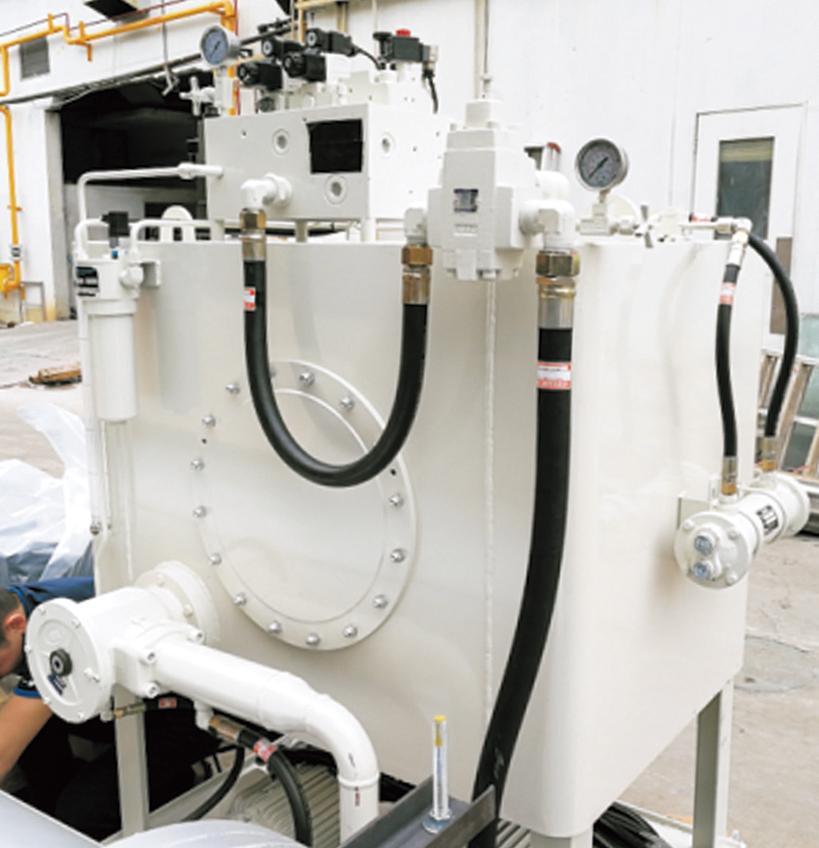

The technical solution adopted by the utility model to solve its technical problems is a rapid laminator, which includes a main frame, an air pump, a cooling water circulation system, a cooling water air cooling system, an electrical control system, a cooling tower and a heat tower structure, Automatic instrument control and automatic display part; the air pump and cooling water circulation system are arranged in the lower part of the main frame, and the cooling water air cooling system is arranged on one side of the main frame, the electrical control system is arranged inside the rack.

The self-control and self-control display part is arranged on one side of the main frame, and the cold tower and hot tower structure part is arranged on the opposite side of the main frame, exposed from the face of the side: the frame fixed with left and right sliding guide rails perpendicular to the upper and lower beams, the air-hydraulic cylinder giving lifting and processing pressure to the cooling tower and the heat tower, the cooling tower composed of the upper block of the cooling tower and the lower block of the cooling tower, the heat tower composed of the upper block of the cooling tower and the lower block of the heat tower, and the inlet of the laminated body located between the upper block and the lower block of the heat tower, it is composed of two parts: a hydraulic cylinder and a cylinder. In order to speed up the cylinder head and cooling, the cooling force buffer and the return of the piston rod, a disc spring is connected to the top of the cylinder piston, and the cylinder is connected with the above-mentioned air pump to control the pressure of the hydraulic cylinder.

The cooling water air cooling system is an automobile radiator. The new type of beneficial effects are: small size, light weight, high degree of automation, firm lamination and bonding, no pattern deformation, no discoloration, product qualification rate of 100, easy operation and maintenance.

The pcb laminator manufacturing method uses a movable platen to press and heat a single-layer printed circuit board layer, and can omit steel plates sandwiched above and below the printed circuit board layer compared to a conventional laminator, and can greatly reduce the weight of the printed circuit board layer and reduce the amount of work of the operator. In addition, the laminated device of the invention can be used more flexibly by directly pasting the film on the single-layer printed circuit board layer. The heating speed of the substrate on which the movable pressure plate pastes the film is very fast, it only takes 30 seconds to 1 minute to complete a film pasting operation, and the film pasting efficiency is very high.

The above is the pcb laminating machine production method, if you need to know more, you can contact us at any time!

Tag:

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas