The working principle of pcb laminating machine

Release time:

2021-07-08

Pcb laminator relates to the field of printed circuit board production equipment, in particular to the printed circuit board on the insulation film of the new pcb laminator, the following together to understand the pcb laminator under the working principle of it!

pcb laminator relates to the field of printed circuit board production equipment, in particular to the printed circuit board on the insulation film of the new pcb laminator, the following together to understand the pcb laminator under the working principle of it!

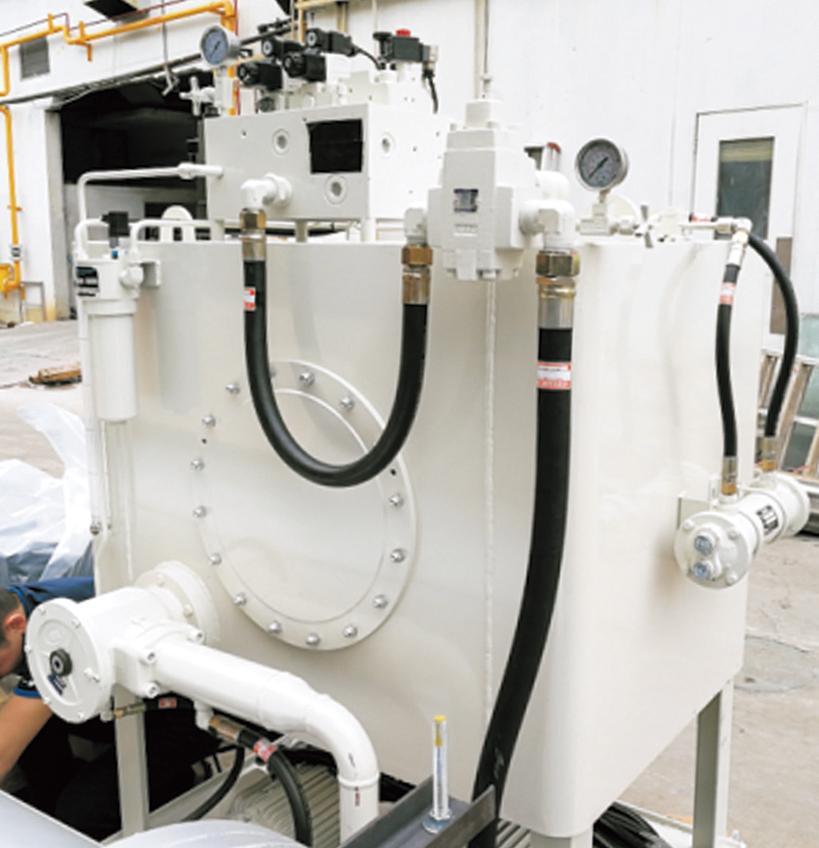

1. A high-speed laminator, characterized in that it comprises a main frame, an air pump, a cooling water circulation system, a cooling water air cooling system, an electrical control system, a cooling tower and a heat tower structure, automatic instrument control and automatic display Part; the air pump and the cooling water circulation system are arranged in the lower part of the main frame, the cooling water air cooling system is arranged on one side of the main frame, and the electrical control system is arranged in the rack, the automatic control and the automatic control display part are arranged on one side of the main frame, and the structural parts of the cooling tower and the thermal tower are arranged on the other side of the main frame

2. The pcb laminator is characterized in that the structure of the cooling tower and the heat tower includes: a frame fixed with left and right sliding guides perpendicular to the upper and lower beams, and air-hydraulic cylinders that apply lifting and processing pressure to the cooling tower and the heat tower, A cooling tower composed of an upper block of the cooling tower and a lower block of the cooling tower; 1. A rapid laminated body, characterized by comprising: a moving inlet of a retained component between an upper block of a cooling tower and a lower block of a cooling tower, a heat tower composed of an upper block of a heat tower and a lower block of a heat tower, and a moving inlet of a laminated body between the upper and lower blocks of the heat tower.

3. pcb laminating machine is characterized in that the upper block of the cold tower and the lower block of the cold tower are separated hollow flat bodies, and their internal cavities are connected with the cooling water circulation system through nozzles. A high-speed laminated body is characterized in that the upper block of the cold tower and the lower block of the cold tower are slidably connected to the left and right sliding guides of the above frame through guides, the upper surface of the upper block of the cold tower and the lower surface of the lower block of the cold tower are respectively provided with thermal insulation liners.

4, the upper block of the thermal tower and the lower block of the thermal tower are two hollow flat bodies with electric heating elements that can be connected to the control power supply, and the upper block of the thermal tower and the lower block of the thermal tower can be slidingly connected to the left and right sliding guides of the frame, hot.

5. The air-hydraulic cylinder is arranged under the cooling and heating tower in the frame and is composed of a hydraulic cylinder and a cylinder. The front end block of the rod of the cylinder abuts on the lower part of the cooling and heating tower, and the front end block of the piston of the cylinder is connected with the disc The spring is connected, and the cylinder block and the cylinder are connected with the above-mentioned air pump to control the pressure of the hydraulic cylinder.

The pcb laminator manufacturing patent is a high-speed laminator including frame, air pump, cooling water circulation system, cooling water air cooling system, electrical control system, cooling tower and heat tower structure part, automatic control and automatic control display part; The air pump and cooling water circulation system are arranged in the lower part of the rack, the cooling water air cooling system is arranged in the rack, the electric control system is arranged in the rack, and the automatic control and automatic control display part are arranged on one side of the rack, the structure part is arranged on the opposite side of the frame. The cooling tower and the hot tower structure are composed of a frame with fixed beams and sliding guide rails, an air-liquid cylinder, a cold tower composed of the upper block of the cold tower and the lower block of the cold tower and the entrance between them. The upper block of the hot tower and the lower block of the hot tower constitute this machine with small volume, light weight, high degree of automation, firm lamination and adhesion, and no deformation or discoloration, the qualified rate of products is high.

The above introduction is the working principle of pcb laminating machine, if you need to know more, please feel free to contact us!

Tag:

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas