PCB laminator device with small volume, energy saving and environmental protection, and good pressure plate effect

Release time:

2021-07-20

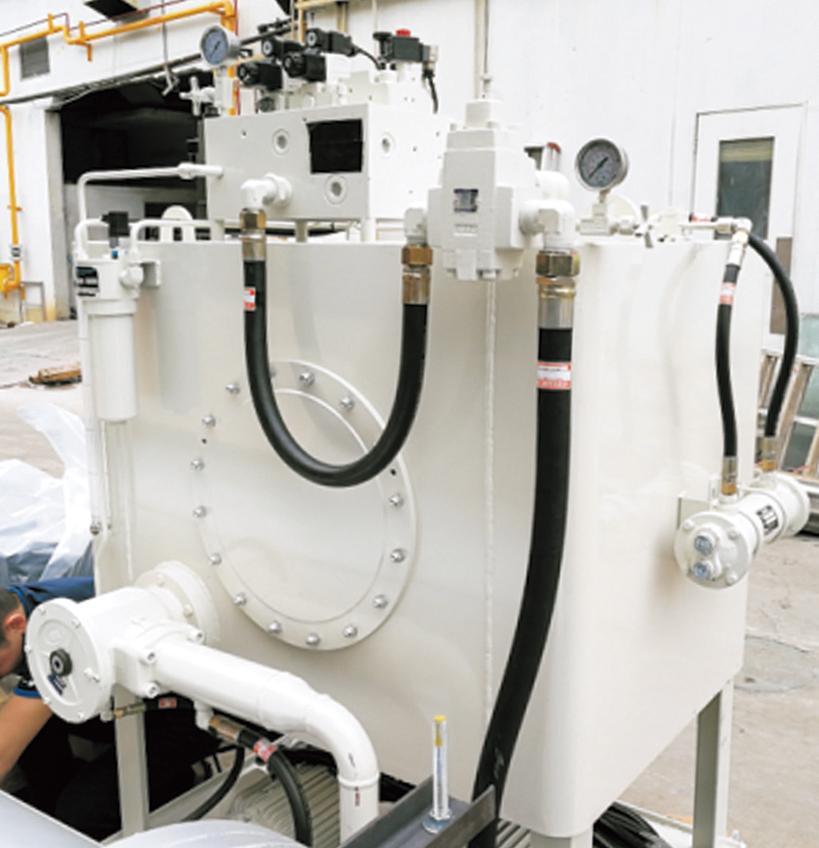

At present, the circuit board has become the main component of circuit interconnection in most electronic products. With the rapid improvement of circuit signal transmission speed and the wide application of high-frequency circuits, higher requirements are put forward for the circuit board. Among them, the circuit board laminating machine, also known as the PCB laminating machine, is one of the main production equipment of the circuit board. Its function is to apply the principle of heating and pressurizing to press the manufacturing materials of the circuit board together to achieve a flat and tight circuit. effect.

Printed circuit board, referred to as printed circuit board. The circuit board is generally composed of copper foil, resin, inner layer and other components, which need to be heated and pressed. At present, the circuit board has become the main component of circuit interconnection in most electronic products. With the rapid improvement of circuit signal transmission speed and the wide application of high-frequency circuits, higher requirements are put forward for the circuit board. Among them, the circuit board laminating machine, also knownPCBThe laminator is one of the main production equipment of the circuit board. Its function is to apply the principle of heating and pressurizing to press the manufacturing materials of the circuit board together to achieve the effect of flatness and tight circuit. currently on the marketPCBThe laminator is heated by kerosene circulation. Although this heating method is easy to control the heating temperature of the laminate, the laminator must be equipped with a hot kerosene tank, which increases the size of the machine. More importantly, this heating method has slow heating speed, large heat loss, and uneven heating of the laminate, which reduces the quality of the circuit board, wastes resources, and increases production costs.

In view of the shortcomings of the existing technology, the technicians provide a small size, fast heating speed, low heat loss, uniform heating, energy saving and environmental protection, and good pressure plate effect.PCBLaminator laminating device. In order to achieve the above purpose,PCBThe technical scheme adopted by the laminating machine laminating device is as follows: aPCBThe laminating device of the laminating machine includes a shell, a vacuum pressure chamber mechanism and a base bracket. The vacuum pressure chamber mechanism includes a pressure chamber, an oil cylinder, a movable plate and a plurality of laminated plates; the pressing chamber is composed of a bracket plate, an oil cylinder fixing plate and a bottom plate Assembled; the movable plate and the laminated plate are driven by the oil cylinder to move up and down along the axial direction of the guide post; the laminate is an electric heating laminate that integrates heating and cooling function; set21Block laminate, all connected with electric heating control system and cooling system. The laminated board includes a board body, a cooling water pipe connected to a cooling system, and a plurality of electric heating pipes electrically connected to an electric heating control system. The plurality of electric heating pipes are arranged in the board body at uniform intervals, and the cooling water pipe is bent in the board body to form a circulation loop. The electric heating tube is a straight electric heating tube that provides18Electric heating tube. The guide ring take-off and landing mechanism includes a take-off and landing guide sleeve sleeved on the guide post, a fan-shaped connecting block and a guide ring connected with the laminated plate. The take-off and landing guide sleeve is matched and connected with the guide ring through the fan-shaped connecting block, and the fan-shaped connecting block is fixed on the take-off and landing guide sleeve through a fixing piece. The upper and lower ends of the take-off and landing guide sleeve are respectively provided with convex ring blocks, the take-off and landing guide sleeve is I-shaped, and the inner side of the fan-shaped connecting block is provided with a clamping groove matched with the convex ring block and the guide ring.

AbovePCBThe beneficial effects of the laminator laminating device are:PCBThe laminate of the laminator laminating device is an electric heating laminate that integrates heating and cooling functions. The electric heating control system and the cooling system can control the heating and cooling operations to be carried out in the same board body. Laminate has18Root electric heating tube, heating evenly. Compared with the laminating machine using kerosene circulation heating,PCBThe laminator has reduced volume, fast heating speed, small heat loss, good paper pressing effect, energy saving and environmental protection.

Tag:

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas