Technical application of high temperature vacuum press!

Release time:

2021-08-02

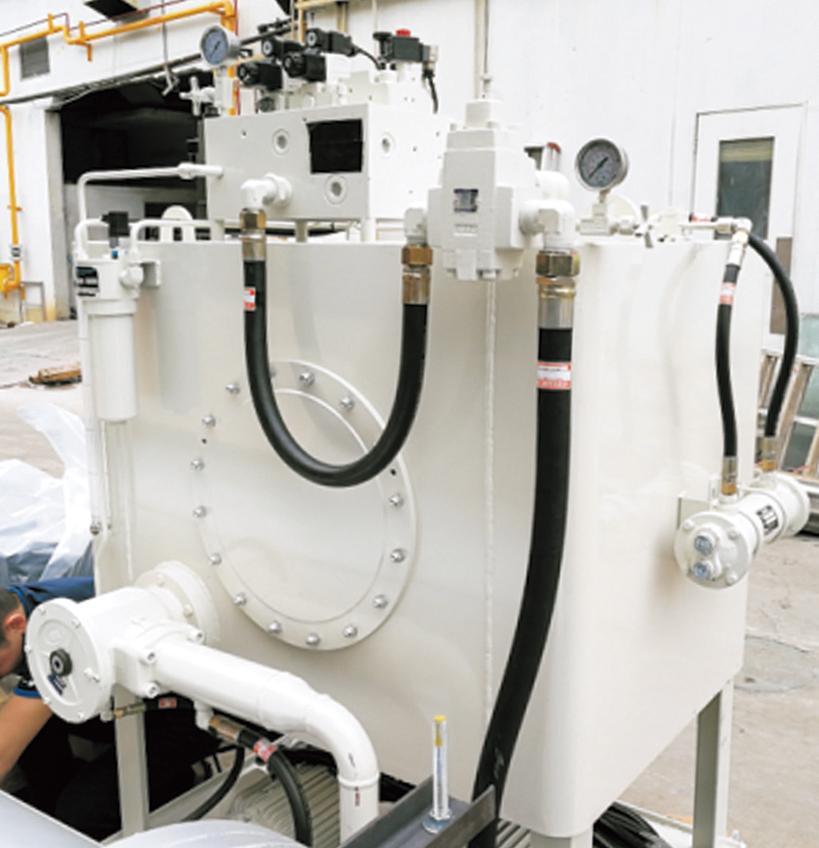

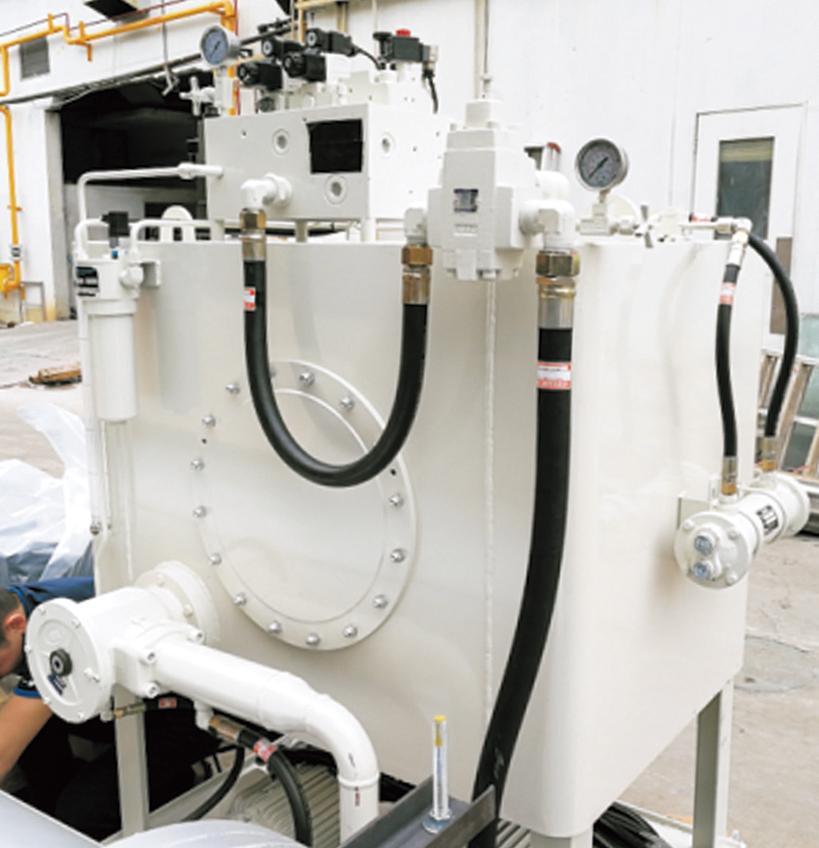

High temperature vacuum laminating machine is a general-purpose flat vulcanizing machine for research and development, so it is also called a laminating machine for research and development. It is a vacuum laminating machine developed by using PCB circuit board as material and lamination technology. High temperature vacuum laminating machine special steering ball head pressure structure, uniform pressure distribution;

High temperature vacuum laminating machine is a general-purpose flat vulcanizing machine for research and development, so it is also called a laminating machine for research and development. It is a vacuum laminating machine developed by using PCB circuit board as material and lamination technology. High temperature vacuum laminating machine special steering ball head pressure structure, uniform pressure distribution;

The high-temperature vacuum laminating machine uses high thermal conductivity materials to transfer heat, and the temperature of the entire working face is the same; selecting excellent thermal insulation materials, good thermal insulation and thermal insulation effects; prefabricated parameters can be called at any time, and temperature and pressure can be set and changed according to processing tasks And time, easy and flexible operation; compact design, matching reliable electronic control, automatic hydraulic, automatic blowing and cooling systems to ensure perfect performance; for laminating up to 8 layers of circuit boards, and a variety of processing that requires strict control of temperature, pressure, and time.

The high-temperature vacuum laminating machine is controlled by a computer program. According to different materials and different process parameters, a high-precision hydraulic system is used to drive high-precision metal plates. While applying pressure to the workpiece, heat is transferred to realize the hot pressing of process parameters such as heating temperature, applied pressure and processing time for the workpiece material, and the separated copper foil, copper clad foil, semi-cured sheet, etc. are hot pressed together, A multilayer circuit board including more than two conductive layers and more than one insulating layer is formed. The core technology is that it is evenly distributed on the surface of the entire workpiece with high temperature and high pressure, as well as temperature and pressure control accuracy, heat preservation and heat insulation effects.

The high temperature vacuum laminating machine uses a special heating structure, which can make the equipment temperature rise at a speed of more than 15 ℃/min, and the high temperature can reach 350 ℃, which can meet the high temperature pressing requirements of microwave materials and graphite materials. The equipment adopts a double-layer heat insulation board design, which can ensure that the outer wall of the equipment still meets the safety requirements at 350°C.

Tag:

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas