If a worker wants to do a good job, he must first sharper his tools. Dongguan clothing, footwear industry to accelerate the transformation and upgrading, it is urgent to "armed" on the latest technology and equipment.

The 2017 China (Dongguan) International Textile and Garment Industry Technology Exhibition and the 2017 China (Dongguan) International Shoe Machine Shoe Material Industry Technology Exhibition will be held from March 29 to April 1. The exhibition attracted more than 300 exhibitors. Exhibitors from China, Hong Kong, Taiwan, Japan, India, Germany, South Korea, Italy, the United States, France and Switzerland and other countries and regions. The exhibition brings together industry elites from all over the world. In 2017, the two major exhibitions will face market changes and customers' demand for high quality. Exhibitors will display high-efficiency automated production equipment, hoping to help customers reduce manpower, improve production efficiency, save energy and respond to environmental protection.

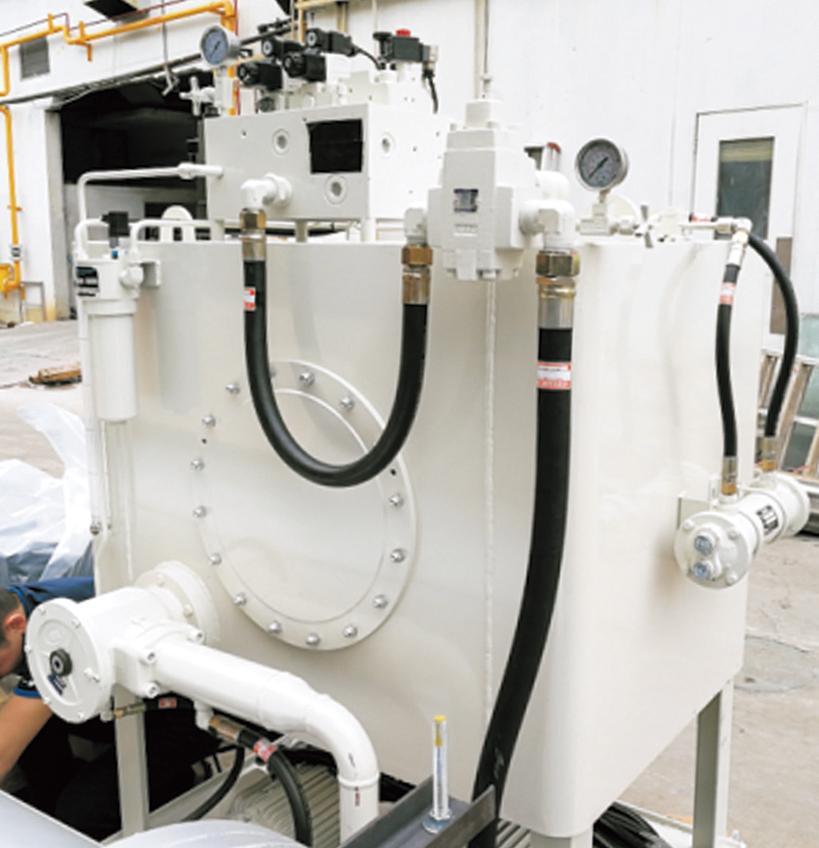

Shoe material industry technology exhibition exhibits include: sole shoe machine, the whole production line, upper production, bag machinery, luggage machinery, leather processing machinery, leather and artificial leather and other exhibits are diverse and dazzling. The exhibitors include Yigao Machinery Co., Ltd., Ridong Machinery (Hong Kong) Co., Ltd., Mingling, Luxin Shoe Machine, Jin Yuelai, Qiyu, Chuanhao, Qifeng, Air Show, TESEO,MeB Bifu, etc.

New equipment significantly increases productivity

Many of the equipment displayed at this exhibition can significantly improve the production efficiency of products.

Lu Xin shoe machine this year brought automatic feeding, brush glue manipulator and a full-automatic cutting machine that can cut 3 times a second. The company also brought a special shoe machine that can sew three-dimensionally for various shapes of shoes, attracting many viewers to stop.

Zheng Guipan, regional manager of Shenzhen Yihefeng Intelligent Sewing Equipment Co., Ltd., said that the company's high-speed embroidery machine is 11.5 meters long, carries 30 two-way needles, and can embroider with 15 colors of threads at the same time.

Zheng Guipan said that compared with traditional embroidery machines, the equipment exhibited by the company this time can not only reduce labor costs by 50%, but also increase production capacity by 70%.

In addition to upgrading equipment, optimizing production processes with data and algorithms can also significantly improve efficiency. Yiaos Software brought APS intelligent scheduling software to the exhibition site for display. Zhong Fang, the company's sales director, said that in recent years, the company has continuously optimized its intelligent scheduling software to better meet the flexible production needs of manufacturing enterprises. At present, the software can be used in clothing, shoes and hats, leather goods, bags and other manufacturing fields.

Through this software, orders entered by manufacturing companies can be quickly converted into production instructions. The algorithm behind the software will generate a joint production plan based on factors such as material reserves and delivery time to ensure that products are completed on schedule and improve the efficiency of corporate capital turnover.